Grout Paper Sheets, Pre-Cut and Scored, for Compressive Strength Testing of Grout and Mortar

EMI makes and stocks the individual grout paper sheets which are used to create grout prisms for compressive strength testing.

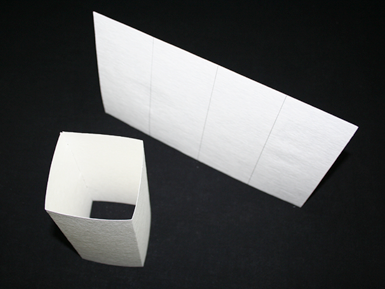

The grout paper is cut to dimensions of 7 1/2″ x 12″ and scored in three places to allow the paper to be folded into a 3″ x 3″ x 7.5″ prism. The grout paper molds are then placed into a cavity created by properly arranging concrete masonry units (CMU) and/or bricks to the same dimensions. The grout is then placed and consolidated into the cavity lined by the EMI grout paper.

The grout paper is cut to dimensions of 7 1/2″ x 12″ and scored in three places to allow the paper to be folded into a 3″ x 3″ x 7.5″ prism. The grout paper molds are then placed into a cavity created by properly arranging concrete masonry units (CMU) and/or bricks to the same dimensions. The grout is then placed and consolidated into the cavity lined by the EMI grout paper.

Not only is this method more economical than the corrugated cardboard boxes which are commonly used, it also meets the guidelines of ASTM C-1019: for a thin, permeable material to prevent bond. In addition the permeable grout papers are rigid enough to help prevent casting irregular shaped specimens which the use of thinner materials can possibly yield. Using our grout papers to create compressive strength specimens in accordance with procedures outlined in ASTM C1019 will eliminate the need to make comparison samples if proposing to employ alternative methods of creating test samples as noted in the standard.” Even if you are making 4 specimens similar to the corrugated cardboard boxes, EMI Grout paper is less expensive per specimen.

How To Create Grout Specimens per ASTM C-1019:

- Assemble concrete masonry units (CMU) and/or bricks (depending on the type of wall being constructed), to create a 3-sided cavity and line it with the EMI pre-cut and scored grout paper.

- Place a non-absorptive spacer block at the bottom of each cell to be filled with grout.

- Close off the fourth side with concrete masonry units (CMU) and/or bricks (depending on the type of wall being constructed).

- Fill the molds with grout and consolidate as outlined in ASTM C-1019 procedures.

- Allow grout to undergo initial set (typically 24-48 hours) before transporting to the laboratory for additional curing and compressive strength testing.

Grout Paper Specifications and Information

- Grout mold – .020 thick rigid, yet absorbent paper (easier to use than paper towels).

- Sheets are cut and scored in the exact dimensions to create a 3″ x 3″ x 7.5″ cell which can be trimmed after initial setting to create a 2:1 height to width ratio prior to capping and testing for compressive strength as outlined in ASTM C-1019: Standard Test Method for Sampling & Testing Grout.

- EMI Grout Paper meets the guidelines of an absorptive liner between the fluid grout and concrete masonry unit (CMU) or brick per ASTM C-1019: Standard Test Method for Sampling & Testing Grout.

- Easy to use – paper sheets scored for folding.

- Produces a better quality sample to be tested for compressive strength in the laboratory.

- Unlike a plastic mold or a cardboard box mold, the paper molds allow the surrounding concrete masonry unit (CMU) or brick to absorb moisture from the grout to simulate the actual processes during construction. This method creates a more representative specimen of in-situ materials for compressive strength testing.

Even if you need to do 4 tests, our grout paper is less expensive.